INDUSTRIAL IOT SUITE

FOR 4.0 COMPANIES

THE NO CODE IIoT SUITE FOR THE SUPERVISION OF INDUSTRIAL PLANTS

Condition monitoring,

production analysis and remote diagnostics

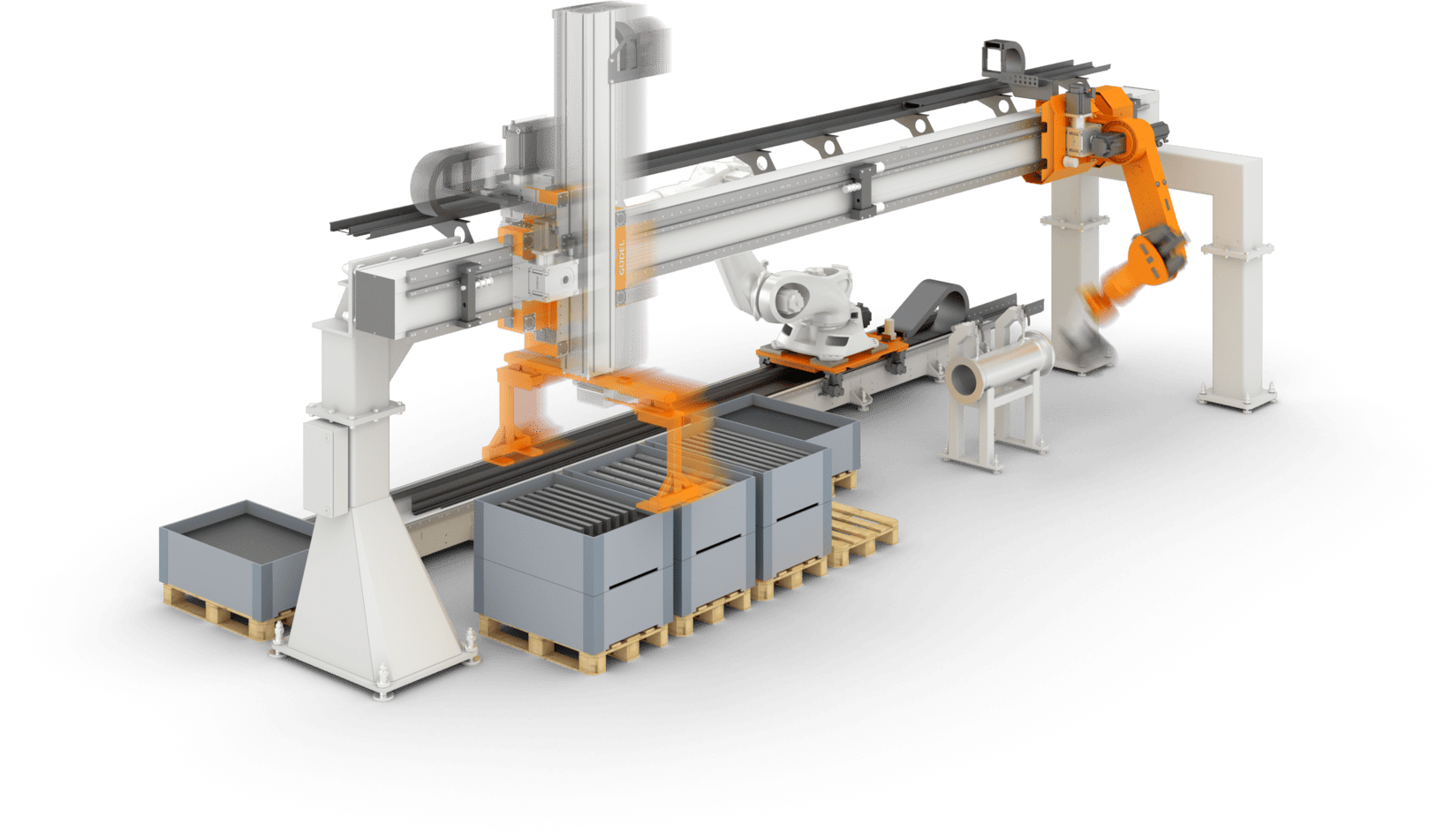

KAINET is a Smart Manufacturing platform designed to meet the digital innovation needs of small and medium enterprises. Enabled to IoT technology and perfectly matching the fiscal benefits of “Piano Transizione 4.0” it is a complete solution for the automation of production processes, condition monitoring and remote diagnostics of devices, machinery and industrial plants.

WHO IS IT FOR?

BENEFITS FOR MACHINE TOOL MANUFACTURERS

4.0 READY MACHINE TOOL

Perfectly in line with the tax benefits of the Transition Plan 4.0

BETTER PERFORMANCES

Greater control over configurability, future development and maintenance

MORE STABLE REVENUES

Reduction of cyclicality of revenues and product-centric sales activities

HIGHER PROFIT MARGINS

After-sales services and parts help maximize profits

CUSTOMER LOYALTY

Stronger relationship during the entire life cycle of the machinery and competitor lock-out

BENEFITS FOR MANUFACTURING COMPANIES

INCREASED PRODUCTIVITY

LOW MAINTENANCE COSTS

REDUCTION OF MACHINE DOWNTIME

LOWER ENERGY CONSUMPTION

INDUSTRY 4.0 BENEFITS

PAY PER USE CONTRACTS

ADVANTAGES FOR SYSTEM INTEGRATORS

4.0 READY PLANTS

CUSTOMER LOYALTY

HIGHER REVENUES

HW/SW INTEGRATED OFFER

PROFIT OF THE NEW

“PIANO TRANSIZIONE” 4.0

Create your own Smart Factory

and accelerate your ROI with KAINET

KAINET is an innovative technological solution, able to to facilitate your digital transformation process. What does it mean? It offers you the opportunity to access the fiscal benefits of the new "Piano Transizione" 4.0 to accelerate the return on your investment.

What are the new facilities

under the TRANSITION 4.0 plan?

DISCOVER MORE

Innovation and Ecology

PROFIT OF THE NEW “PIANO TRANSIZIONE” 4.0

Create your own Smart Factory

and accelerate your ROI with KAINET

KAINET is an innovative technological solution, able to to facilitate your digital transformation process.

What does it mean? It offers you the opportunity to access the fiscal benefits of the new “Piano Transizione” 4.0 to

accelerate the return on your investment.

What are the new facilities

under the TRANSITION 4.0 plan?

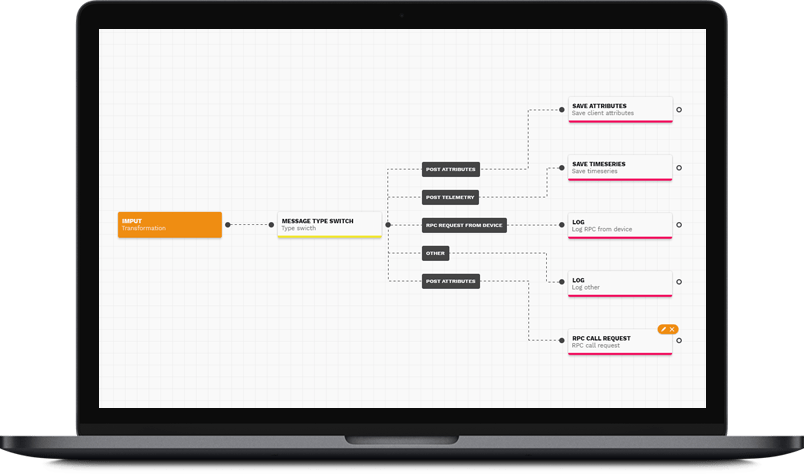

HOW IT WORKS

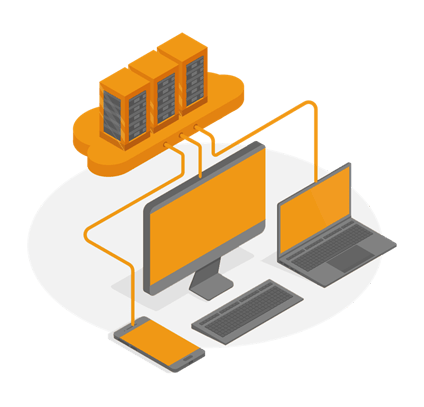

KAINET is the digital bridge between the factory (OT) and your computer systems (IT).

IIoT DEVICE

Connect

Connect all machinery and devices in your industrial plant with IoT technology.

IoT GATEWAY

Transfer

Transfer data from machines with different communication protocols.

![]()

Process and Analyze

It processes and analyzes all incoming data in one intelligent platform.

USER DASHBOARD

View and Decide

Display production data in real time through simple and intuitive graphics.

ARCHITECTURE 4.0

Discover the technical components that KAINET, our Industrial IoT platform for digital manufacturing, is built with.

Technologies

MICROSERVICE APPROACH

The KAINET platform has been designed using a microservices architecture.

This means that this can be distributed and replicated on multiple nodes, compatibly with the computational load.

Microservices communicate with each other thanks to Spring Cloud acting as service discovery.

PRODUCE MORE.

YOU WASTE LESS.

REDUCE COSTS.

Source: McKinsey Digital and University of Padova

Increase in turnover

+39%

Maintenance costs

-30%

Increased productivity

+54%

Production costs

-60%

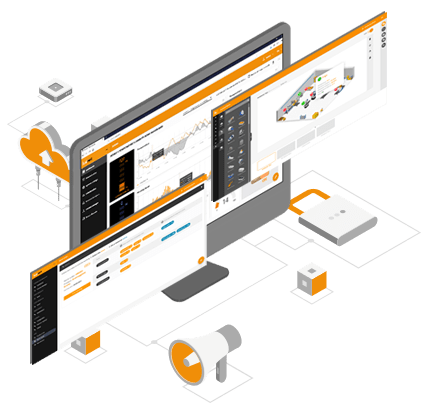

DISCOVER WHAT

YOU CAN DO WITH KAINET

1

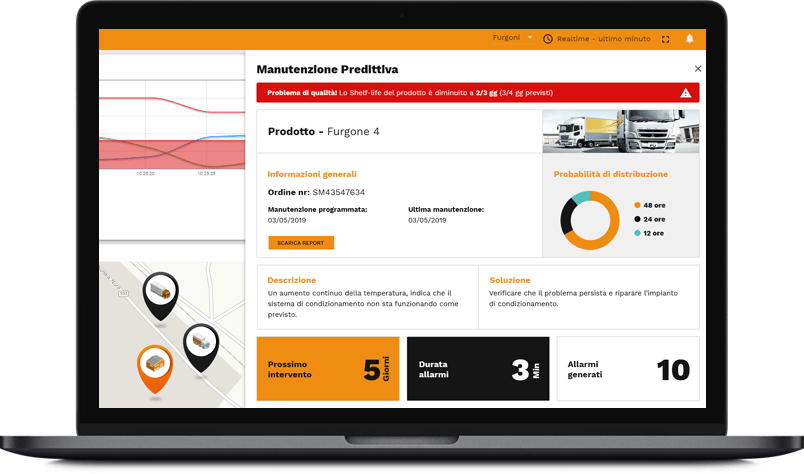

Predictive maintenance

of machinery

By analyzing machine telemetry data over time (Time Series) KAINET is able to identify wear signals and predict failures before they occur. It suggests maintenance planning without stopping production.

DISCOVER WHAT

YOU CAN DO WITH KAINET

2

Remote management

of business processes

KAINET offers an overview of all production lines and machinery within your plant. Send commands (start&stop) to operators and machines and activate appropriate alarms in case of anomalies.

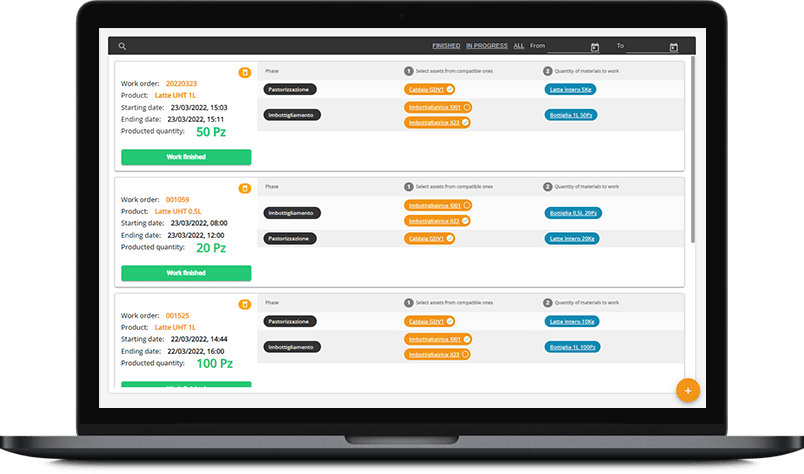

DISCOVER WHAT

YOU CAN DO WITH KAINET

3

Real time analysis

of production

KAINET always keeps production under control. It checks incoming orders, quantities of products being processed and rejected materials as well as efficiency on a single line and daily downtime.

DISCOVER WHAT YOU CAN DO

WITH KAINET

Predictive maintenance

of machinery

By analyzing machine telemetry data over time (Time Series) KAINET is able to identify wear signals and predict failures before they occur. It suggests maintenance planning without stopping production.

Remote management

of business processes

KAINET offers an overview of all production lines and machinery within your plant. Send commands (start&stop) to operators and machines and activate appropriate alarms in case of anomalies.

Real time analysis

of production

KAINET always keeps production under control. It checks incoming orders, quantities of products being processed and rejected materials as well as efficiency on a single line and daily downtime.

WHAT WE OFFER YOU

Everything you need in one solution IIoT

compliant with the new "Piano Transizione" 4.0

HARDWARE

SOFTWARE

One-off investment

(with an optional annual fee for software update)

INTEGRATION SERVICES

As needed

(with free analysis)

KAIBOX

Compact industrial system,

scalable and performing

The KAINET platform comes with hardware specifically designed for different types of industrial environments.

Highly performing, it withstands severe conditions of use such as shock, vibration, dust, humidity and heat.

Sized according to specific needs with scalable processing and storage power.

* The product image is purely indicative. For KAINET we use

Industrial PCs of the best brands, such as Advantech, DELL, Allen-Bradley, etc…

KAINET SUPPORTS THE MAIN INDUSTRIAL COMMUNICATION PROTOCOLS

KAIBOX

Compact industrial system,

scalable and performing

* The product image is purely indicative. For KAINET we use industrial PCs of the best brands, such as Advantech, DELL, Allen-Bradley, etc..

The KAINET platform comes with hardware specifically designed for different types of industrial environments.

Highly performing, it withstands severe conditions of use such as shock, vibration, dust, humidity and heat.

Sized according to specific needs with scalable processing and storage power.

KAINET SUPPORTA I PRINCIPALI PROTOCOLLI DI COMUNICAZIONE INDUSTRIALE

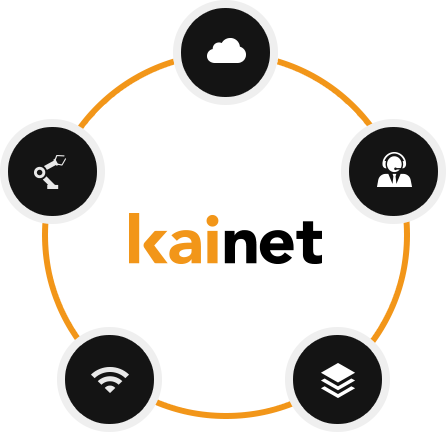

CLOUD, EDGE, ONBOARD OR HYBRID

IIoT technology offers great opportunities for companies, but only if managed properly.

KAINET is available in four versions: Cloud, Edge, OnBoard or Hybrid. Find out which one is the best solution for your business.